UVA LIDKÖPING is Sweden`s largest machine tool manufacturer. We specialise in the manufacture of precision grinding systems.

Our goal is to give you accuracy, efficiency and reliability through our products, our process knowledge and development, customer support and service. Through close cooperation with end-users, we ensure a correct and profitable solution for you, the customer.

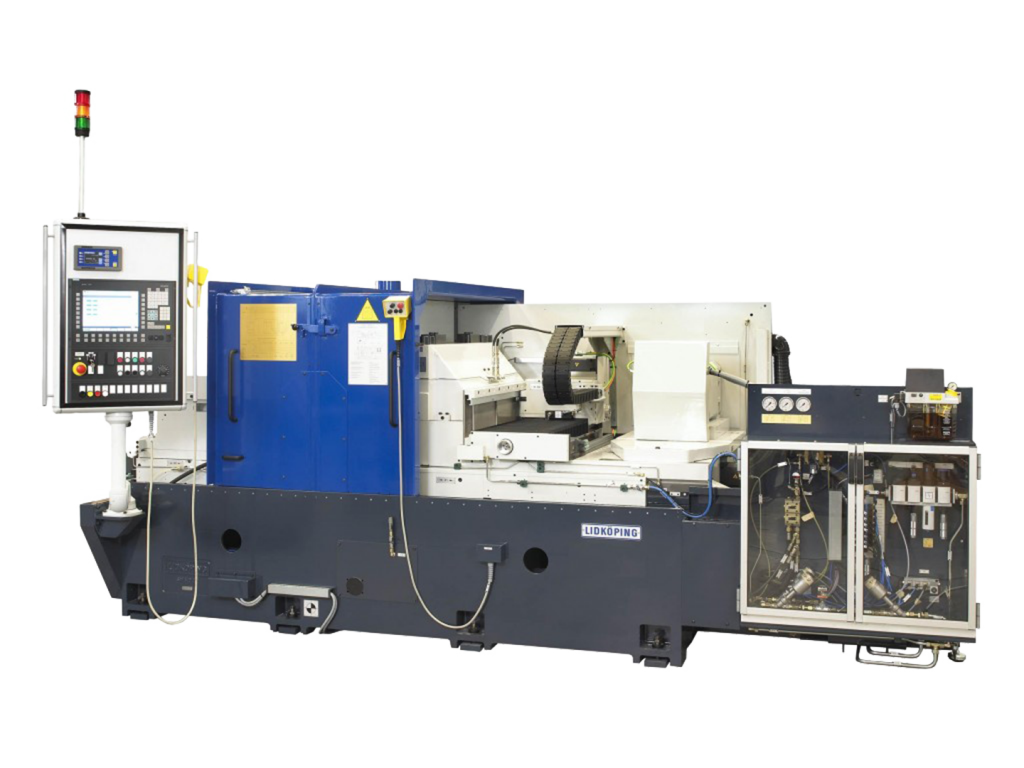

The LIDKOPING centerless grinder is designed and manufactured to meet practically any challange in precision grinding. The Centerless is the foundation stone of our reputation as a leader in precision grinding technology.

Machine Concept

Infeed or Throughfeed Grinding

The LIDKÖPING centerless grinding machine offers two main type of grinding operations, infeed or throughfeed grinding depending on the shape of the work piece.

Grinding Spindle

Main spindle drive permits constant grinding speed.

Regulating Spindle

Is servomotor driven via a hypoid gear. Speed range 10 rpm to 750 rpm.

Spindle Drives

Belt and pulleys are used as main spindle drive for the grinding spindle.

Cartridge-type Spindles

for grinding and regualating wheel enable quick wheel change. Wheels can be mounted directly on spindles, or on a seperate wheel mount.

Grinding Wheel

is dressed by a servomotor-driven hydrostatic CNC dresser with fixed diamond or diamond form roller.

Regulating Wheel

is dressed by a servomotor-driven hydrostatic CNC dresser

Regulating Wheel Headstock

can be fed manually, or via a servomotor with pre-loaded ball screw.

Adjustable Work Blade Support

can be height set manually or by servo motor.

Spindle Drives

Siemens main spindle drive is used for grinding spindle. Servo motors are standard for regulating wheels.

Control system

The Centerless can be equipped with either SIEMENS or FANUC control systems.

Centerless throughfeed

Centerless throughfeed Centerless infeed

Centerless infeed